Really interested in seeing one of our new models built? Join us as we photo/video each step of the construction process. We go from mold to sea trial and beyond.

We begin with the new NorthCoast 230CC Deep V- a very fine example of our build process.

MISSION accomplished

Build exceptional boats that are seaworthy, sea-kindly, forged to endure the toughest conditions found on the NorthCoast of anywhere.

Construction

Experience the feel of durability. It’s an understatement to say New England testing grounds are “typically rough”. We have to be ready to take on the sea and her extreme nature. So we design and build all NorthCoast models to be very strong and to perform where others may fail.

A QUICK BRIEF

Overbuilt using hand laid woven roving bi-axial fiberglass mat which means stronger, while lighter, requires less horse power and more fuel efficient. Smart design. You don’t have to spend more unnecessarily.

Vinyl Ester resin skin coat for extended durability, flexibility, UV protection- and great looks. General purpose resin is used for the interior build.

FRP integral grid system is foam filled for flotation, (our boats are all level flotation), repels moisture, and transfers engine torque into speed, and stiffness, that makes the boat feel bigger, feel heavier, but without the added cost of useless weight.

No Wood! less water intrusion and longer lasting. Better performance.

We design and build them for a DRY Ride as the Sea demands it!

Reverse chines for stability at rest

Aggressive longitudinal strake provide

Additional lift and water displacement

Provide great tracking, fuel economy, handling, and overall PERFORMANCE

Cored hull sides – (M80) in 190CC, 210CC, 215HT, 230CC and 235HT, (Foam core) in the 255HT, 285HT, 315HT.

Penske board transom and where any added strength for mounting hardware is needed for added strength and a solid fiberglass bottom.

Built for reliability and exceptional fishing performance

NorthCoast 285HT

“NorthCoast Boats designers and craftsmen deeply understand the importance of their work”- Jose DaPonte Owner C&C Fiberglass / NorthCoast Boats

The true nature of this product is best witnessed on Stellwagen Banks as huge Blue Fin Tuna are being brought over the gunnels of even our smallest center or off Newport, Rhode Island where very large Striped Bass, Bluefish and many other species are the target. Being modest, (for Anglers) Our “fish to boat” size ratio likely has no equal.

Our production facility is set up to provide manufacturing flexibility such as the ability to personalize your boat and provide a wide variety of amenities a family may also require.

Design

Latest CAD technology is utilized in support of our form follows function design philosophy. Simple and Strong!

Designed and built to ABYC standards and most importantly, Jose’s standards.

Product development input: Customers, Captains / Brand Ambassadors.

Must fulfill NCB promise- Rugged to last, Versatile to expand your fishing experiences, and Fishing Performance second to none.

Construction Team of expert craftsmen, and in some cases multiple generations all work in a Family environment. Headed by Joe DaPonte, Rosa DaPonte, and their sons Cesar and Craig.

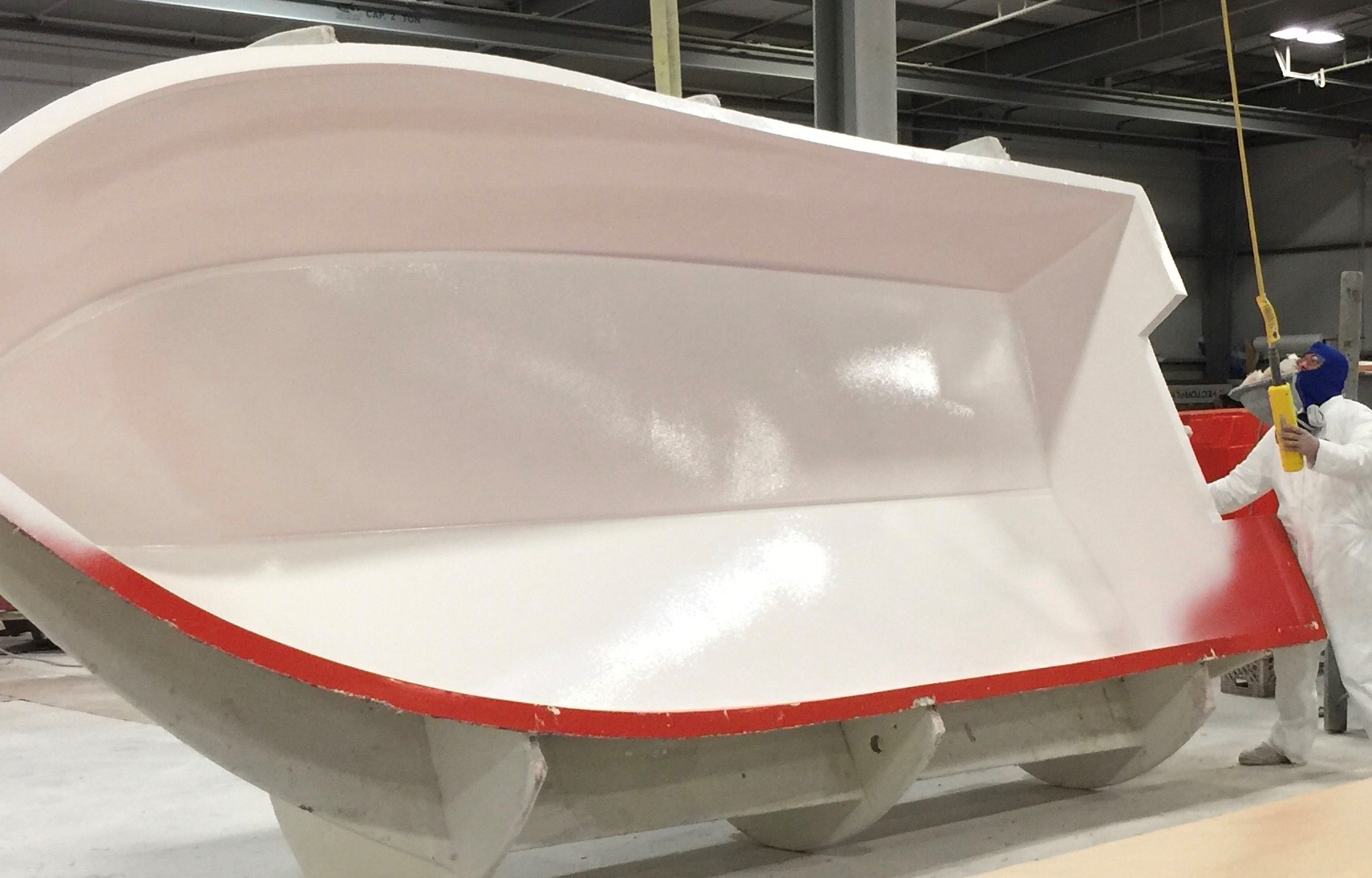

Mold room: “Smell the resin”. Overhead crane, temperature controlled, heated floors, clean, a million moving parts and always busy.

Fabrication

Hull mold preparations- Regular quality inspections and maintenance. Although each mold starts out as new, mold replacement would occur if and when needed. Buffed to a shine to provide ease of hull, deck, or small part removal. Sprayed Gelcoat targeting a thickness of 15-18mls, is reinforced with woven roving bi-axial fiberglass mat saturated with Vinyl Ester Resin, covered with M80 or foam core material and an additional layer of fiberglass. (actual materials thicknesses and schedule proprietary)

Custom colors also available…

Deck sole and Cap parts are taped off for two tone non-skid areas and gelcoat color of choice sprayed. Reinforced by fiberglass mat followed by a ¾” thick foam core to support weight as you walk, all sandwiched between more fiberglass mat and (GP) general purpose resin.

Trim and Patch Room: All parts are trimmed and then prepared for assembly. Preparation includes gelcoat repair of chips that could occur upon mold removal, buffing the parts, and spraying waterlines. Our boot stripes are Awlgrip, NOT tape.

Assembly Room: All hardware such as stainless steel fittings, deck hatch latches, and hinges are mounted on the deck sole part, while all below deck components are installed: These include fuel tanks, fill hoses, filters, batteries, through hulls for head discharge, wire runs etc. Hand rails, rod holders, stainless steel cleats, anchor roller are installed on the foredeck and gunnels. Keep in mind that a very hard nonporous composite (Penske like our transoms) is embedded everywhere a component is through bolted. The console is rigged nearby for steering, electronics, engine gauges, and compass is mounted.

Hull / deck is sealed with 3M 4000 adhesive and joined by mechanical stainless steel fasteners

Console mounted and T-Top bedded in adhesive and mechanically fastened

Engine installations –mounted through Penske board transom – set up by our Certified Mechanics

Final Quality Control inspection and Sea trial where we test every system on board to ensure it’s working properly prior to delivery to your NorthCoast Dealer.

Detail for delivery: We go over every inch of the boat- one more time!